The UWB positioning and chemical plant personnel positioning management solution developed by 95power adopts the ultra-wideband UWB positioning technology of micro-energy information. By deploying UWB positioning base stations in the chemical plant personnel activity area, UWB is equipped for the positioned objects, such as staff, vehicles and assets. Positioning tags (such as UWB positioning badges, wristbands, etc.) can accurately locate the positions of UWB positioning tags on employees, vehicles, and assets in real time, and display the location information of employees, vehicles, and assets in the factory control center. Monitoring, safe area management and control, real-time vehicle trajectory monitoring.

The UWB positioning solution of micro-energy information can provide convenient and fast high-precision positioning technical support for the positioning management of chemical plant personnel, vehicles and materials, and assist in the standardization and information construction of chemical plants.

Targeting objects: on-the-job employees or visitors, factory vehicles (such as forklifts, AGV trolleys, etc.), assets and equipment.

Positioning accuracy: Generally, the error is 10 cm-30 cm according to the positioning scene.

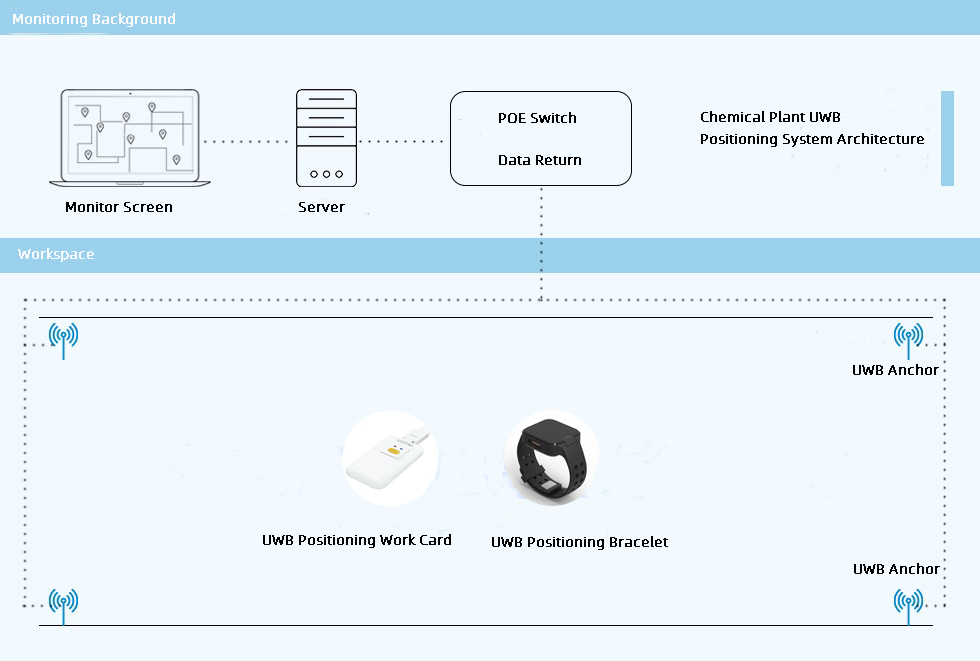

Chemical plant UWB positioning management system consists of: display terminal, UWB positioning engine, UWB positioning base station, UWB positioning label.

(1) Display terminal: The coordinates of the positioning tag calculated by the UWB positioning engine should be displayed on the display terminal (PC, tablet computer, mobile phone).

(2) UWB positioning engine: The UWB positioning base station sends the original position data to the UWB positioning engine through the network in real time, and then the positioning engine runs the positioning algorithm to calculate the real-time coordinate position of the personnel, vehicles, or materials equipped with UWB positioning tags in real time.

(3) UWB positioning base station: The UWB positioning base station communicates with the positioning tag through the UWB signal, and then solves it through the positioning engine to realize the precise real-time positioning function of the UWB positioning tag.

(4) UWB positioning tag: Equip the person, vehicle or equipment to be positioned with a UWB positioning tag. The positioning tag transmits UWB signals and communicates with the UWB positioning base station, so that the tag itself can be positioned. The UWB positioning tag can be a wristband type, a badge type, a module type fixed on a helmet, or a material type according to the positioning scenario.

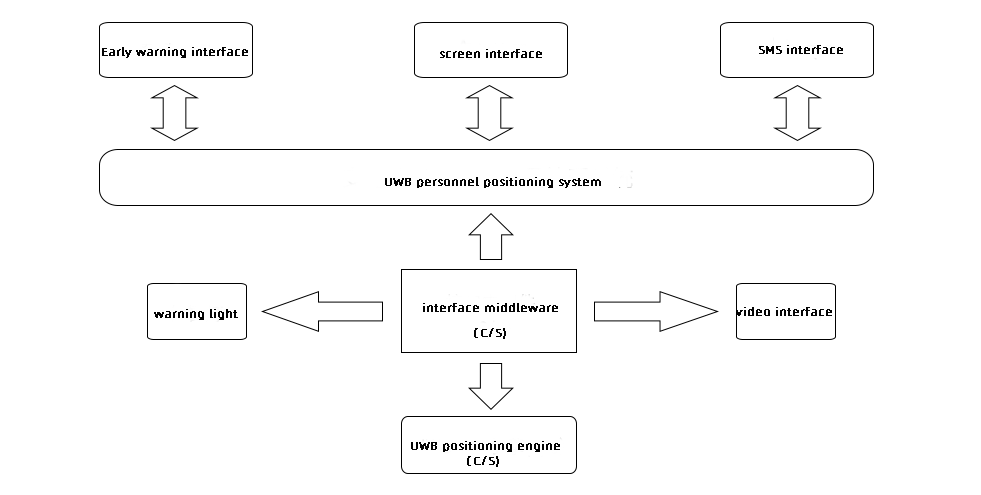

According to the design of the UWB positioning system architecture, the connection, data interaction, business processing, etc. among various functional subsystems are implemented and managed by the interface subsystem, which mainly include the following interfaces:

(1) Real-time positioning and tracking of personnel, vehicles or materials

UWB positioning base stations are deployed in the chemical plant activity area, and the display terminal in the background can check the real-time distribution of the located employees, equipment or vehicles at any time, solving the problem of difficult real-time monitoring.

(2) Employee regional statistics and electronic roll call

Chemical plant operation managers can view information such as the current number of people who should arrive, the number of people who actually arrive, the number of people who are missing, and the number of people who have not arrived on the terminal.

(3) Historical track storage and playback

Through the UWB positioning system, the historical movement trajectories of the located employees, vehicles or materials can be viewed, every detail can be traced back, there is evidence for accountability, and abnormal movement trajectories can also be analyzed.

(4) Security camera linkage

(5) Electronic fence function

Electronic fences can be set up in certain specific areas of the chemical plant to monitor the entry and exit of people in this area

(6) Behavior monitoring function

Behavior monitoring of positioning objects can be carried out in the set area, including overtime monitoring, motion monitoring, crowd monitoring, etc., intelligent management, and improve the ability to respond to rescue in a timely manner.

(7) One-click call for help in dangerous situations

(8) Alarm function

Including real-time early warning, various types of early warning (SOS, low power, offline, etc.), early warning data recording and analysis, etc.

Fast reply in 30 minutes

Fast reply in 30 minutes